mini CRDS – Compact Size, High-Accuracy, High-Sensitivity, and High-Speed Response measurements—utilizing Shinyei’s innovative spectral and optical technologies.

mini CRDS

Trace Moisture Measurement Range in Gas

12 ppbv ~ 20 ppmv(-100 ~ -55 ℃DP)

Size ✅Compact and lightweight

Performance ✅High sensitivity ✅High accuracy ✅High-speed measurement ✅High reliability

Functionality ✅Easy operation ✅Minimal design

Paper

A miniaturized trace-moisture sensor based on cavity ring-down spectroscopy

H. Abe, K. Hashiguchi, D. Lisak, S. Honda, T. Miyake, H. Shimizu

Sensors and Actuators A: Physical 320 112559-112559 2021年4月

Improvement of spectral resolution in a miniaturized trace-moisture sensor using cavity ring-down spectroscopy: Performance evaluation using a trace-moisture standard in He

H. Abe, M. Amano, K. Hashiguchi, D. Lisak, S. Honda, T. Miyake

Sensors and Actuators A: Physical 114146-114146 2023年1月

Technical article * Japanese only

ガス中の微量水分計測のトレーサビリティ体系と二次標準機の開発

小型CRDS微量水分計の実用化

計測標準と計量管理. 2024, 74(1), pp 21-29

DewTracer mini CRDS-H2O has been developed with cooperation of the National Institute of Advanced Industrial and Technology (AIST).

Features

High-Reliability Absolute Measurement Method

The mini CRDS employs the highly reliable absolute measurement technique known as CRDS (Cavity Ring-Down Spectroscopy). This method directly calculates trace moisture in gases by analyzing the decay time of laser light that is reflected multiple times within a cavity.

The absolute measurement method CRDS provides superior precision and outstanding stability compared to relative techniques such as capacitance or phosphorus pentoxide methods, which are based on calibration curves.

By measuring the time constant of light attenuation within the cavity, it is unaffected by laser intensity fluctuations and significantly reduces factors that cause drift. These advantages extend calibration intervals, reduce maintenance, and ensure long-term stability and reliability.

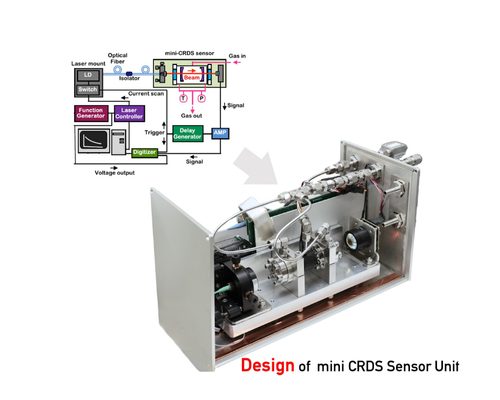

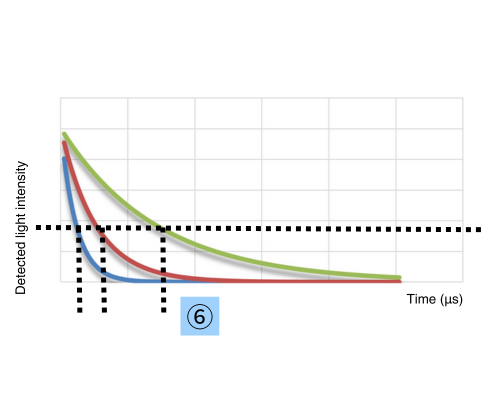

mini CRDS Measurement Principle

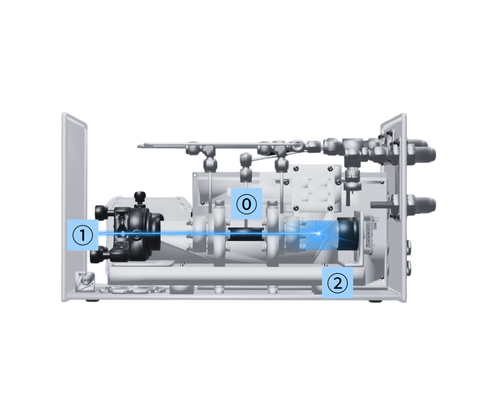

⓪ The sample gas flows into a cell equipped with high-reflectivity mirrors at both ends.

① A laser beam is injected into the cell from one side.

② The intensity of the laser light transmitted through the cell is detected.

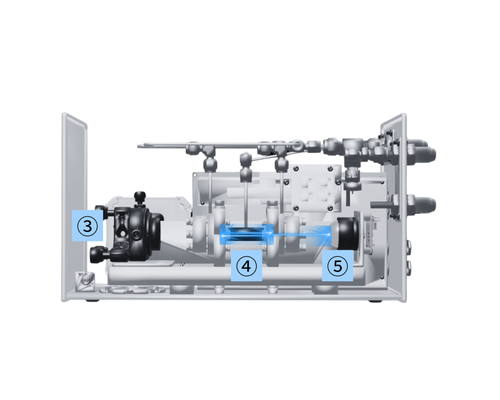

③ The injection of the laser beam into the cell is stopped.

④ Immediately after step ③, the laser light reflects tens of thousands of times within the cell (resulting in an effective optical path length exceeding 3 km inside a 5 cm cell).

⑤ During this period, the intensity of the laser light transmitted through the cell decays according to the moisture in the gas.

⑥ The moisture content is calculated based on the time it takes for the detected laser intensity in step ⑤ to decay to a certain rate (ring-down time).

Non-Contact Measurement with High-Speed Response

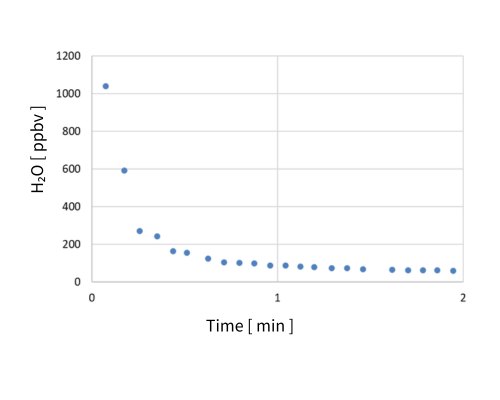

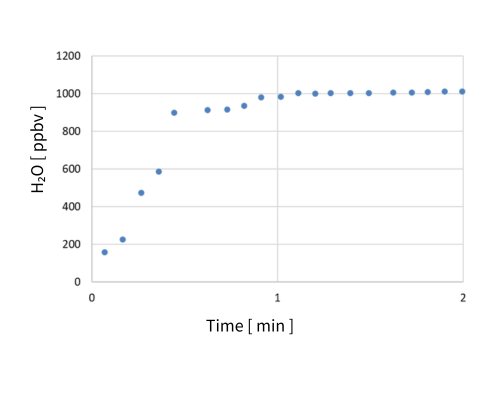

By measuring the decay time of laser light reflecting multiple times within the cavity, moisture in gas is calculated instantly with high precision. This non-contact optical method enables high-speed trace moisture measurement, responding to sudden changes in concentration within seconds.

1000 ppbv → 50 ppbv

63% Response 15.4 s

90% Response 52.4 s

(Measured Gas : N₂)

50 ppbv → 1000 ppbv

63% Response 26.5 s

90% Response 37.4s

(Measured Gas : N₂)

Service & Support

The mini CRDS is developed and manufactured in Japan. Additionally, a reliable support system is in place in various countries. From consultation during the consideration phase to installation, measurement assistance, and ongoing maintenance, we provide comprehensive services and swift support, ensuring reliability and efficiency.

A calibration system for CRDS is established, utilizing a trace moisture generator and a reference instrument that is traceable to Japan’s national standards. Comparative calibration is performed for all units at the time of shipment and during regular calibration intervals.

Products & Services

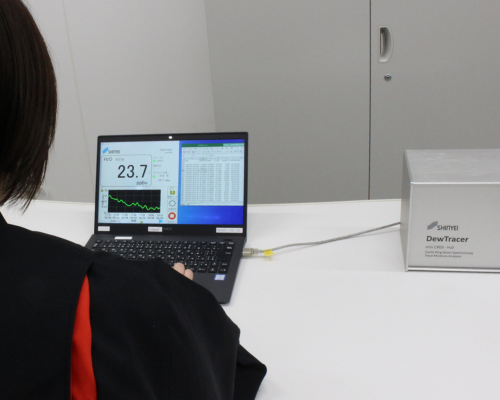

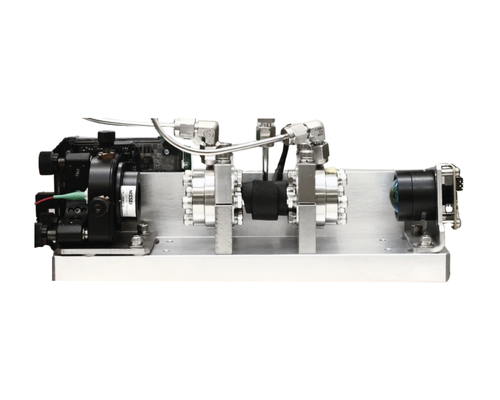

DewTracer mini CRDS-H₂O

(OEM Unit)